UNITED

STATES PATENT OFFICE.

HENRY

BLAIR, OF

GLEN ROSS, MARYLAND.

SEED-PLANTER.

Specification of Letters Patent No. X8447,

dated October 14, 1834

[This

text has been copied from a patent record that is handwritten

(on behalf of Henry Blair). The text as transcribed may contain errors,

and does contain gaps, signified with question marks, where the

original was illegible. A link to images of the handwritten patent is

provided at the end.]

To all to whom these

presents shall concern:

Be it known that I, Henry Blair of Glen

Ross in the county of Montgomery, and the State of Maryland, have

invented a new and useful improvement in the machine for planting corn,

called the corn planter, and that the following is a full and exact

description of the construction and operation of the same, as invented

or improved by me.—

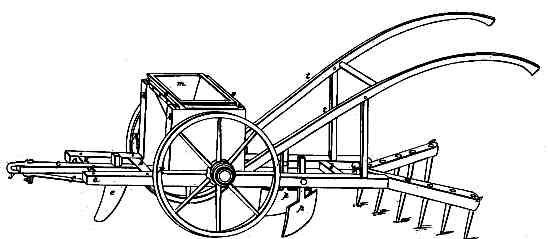

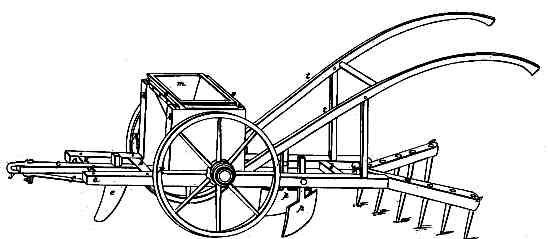

The frame of the machine is made as

follows. Two side pieces four feet six inches long ? ? two

cross pieces being tenoned into them, one at ten inches from the end

that will make the front of the machine, and the other at fourteen

inches from the other end or back; the timber of which this frame is

made is three by four inches. The beam to which the horse is to be

attached, is twenty inches in length, tenoned into the front cross

piece, in the middle between the two side pieces, and there is a brace

piece of timber, one by five inches, which passes through a mortise cut

into the beam. The ends of this piece are tenoned into the side pieces

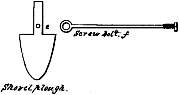

within two inches of their ends. To this beam is affixed a shovel

plough to make the furrow, the plough bar passes through the beam

sideways between the front cross piece and the brace above mentioned,

and is fastened on the top with a ?. A ? ? passes thru’ the

plough bar, made fast on the front with ? and screws; and the other end

has a hole through which passes the clevis bolt; the end of the beam is

provided with a ? ? to which is ? a ?

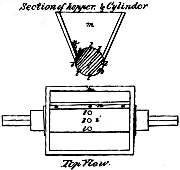

On the top of the two side pieces are

fastened two head blocks fourteen inches long, five and a half high and

three thick. They are tenoned into the side pieces within sixteen

inches of the front and a hole is cut through each, to receive a

cylinder hereafter mentioned. The dropping cylinder is six inches in

diameter, between the head blocks and at each end there is a space of

three inches in length that is reduced to four inches diameter which

forms the bearings of the cylinder and work in head blocks above

mentioned; it then extends six inches (on each side) out side of the

head blocks, and is there permanently attached to wheels of two feet

six inches in diameter. There are holes in the cylinder on its

periphery sufficiently large to hold two, three or four grains of corn;

these holes may be of any number as the number of the holes, and the

diameter of the wheels will regulate the distance at which the corn is

to be dropped. A box or hopper is constructed immediately above the

cylinder, which covers about one third of its diameter, and extends the

whole length of the cylinder between the head blocks. This box or

hopper can be made to hold two or three gallons. The front part of this

hopper, that is, the side towards which the cylinder revolves, is

provided with a bar of iron extending the whole length of the hopper,

one inch wide and a quarter of an inch thick, bevelled to an edge from

the top; the lower surface of this iron hard rides on the cylinder to

prevent the grains of corn from crowding in between the cylinder and

the edge of the box or hopper.

There are two wooden braces which are

made fast to the front and back of the hopper, by means of ? ? that

extend from one head block to the other and are provided with a ? at

each end so arranged as that when either the surface of the cylinder or

the edge of the hopper wears out by turning the ? ? edge of the hopper

can be made to rest on the surface of the cylinder. Between the

cylinder and the back cross piece is to be attached by means of screw

bolts to the inside of the two side pieces two shovels made right and

left ?? the earth into a ridge. Eight inches behind the back cross

piece is a wooden … ??…. To

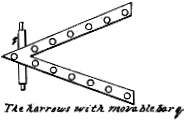

this ? ? is attached a harrow made of two pieces of wood, put together

in a triangle having its base open and its apex attached to the bar

just mentioned. The teeth which are inserted into the harrow are nine

inches long at the apex of the triangle and increase in length until

they reach eleven inches at the base of the triangle. The back part of

this harrow will be at liberty to play up and down, having its front

part attached to the ? bar. The handles are four feet long, having

their lower ends let into the lower part of the head blocks and their

upper ends elevated to two feet seven inches above the frame; they are

framed in the usual manner.

Operation:

When the horse draws the machine the shovel plough makes a furrow to

receive the grain; the cylinder in revolving with the wheels to which

it is permanently attached, catch the grains in the holes (which are

made on its periphery) as they pass through the hopper and lets them

drop into the furrow; the ? then throw the earth into a ridge over the

grains & the harrow passing over it levels the earth and

carries the large clods and stones away. The proportions herein stated

may be varies at pleasure.

What I claim as new and as my invention

and for which I ask Letters Patent, is, the general arrangement and

combination of the several parts. As a further illustration of my

invention, I refer the model and drawing which accompany this.

In testimony that the above is a full

and exact description of the construction and operation of my machine

as invented or improved by me. I have hereunto subscribed my hand this

first day of September in the year of our Lord one thousand eight

hundred & thirty four.

More Information:

Corn

Planting Machine short

article from The

Mechanics' Magazine (1836).

Cotton

Planter, Henry Blair's Patent 15