|

Sir Thomas Bouch

(25 Feb 1822 - 30 Oct 1880)

English railway engineer.

|

The Tay Bridge

by A. Grothe, C.E., Manager Of The Tay Bridge Contract.

from Good Words (1878)

Thomas Bouch

[p.40] IN the days of old, when our grandfathers were boys, a journey from Edinburgh to places north of the Tay was rather a serious matter. The time when the Antiquary and his young friend travelled by the “Hawes Fly,” and had to “tarry a day at the South Ferry for lack of the tide,” does not date a hundred years back; and how has the aspect of travelling changed in that time! If Monkbarns and Lovel now went down to the Waverley “laigh shop” (Anglic�, cellar) of Mrs. Macleuchar, alias the North British Railway Company, the “diligence with three yellow wheels and a black ane” would be ready to leave somewhere near the appointed time, and tide or not, a swift and commodious steamer would be waiting to take them to the other side of the water. There again their conveyance would be ready. A ride of an hour and a half, another short passage by steamboat, another hour’s ride, and they would find themselves at Fairport, having gone over the whole distance in four hours instead of twenty-six, and that in a most comfortable manner, compared with their experiences of a century ago. Whether they would be satisfied with the change, and consider that no further improvements were required, must remain an open question. But unless they had turned the hundred years to very good account, and had acquired qualities quite different from ours, they would probably soon join their fellow-travellers and grumble at the slowness of the train which was literally creeping along at a rate of twenty-five miles an hour. They would get impatient at the vexatious delay at the ferry, two minutes being lost by the transference of the luggage-trucks to the boat. And while sitting in a comfortable saloon, sheltered against the inclemency of the weather, they would vent their grievances about the want of care on the part of the Company, evident from the fact that they did not provide for the travellers so well as these could have done for themselves in their own drawing-rooms. By thus thinking and speaking they would be acting precisely as 99 per cent, of the travellers on the line through Fife do now. At first sight it seems unreasonable that it should be so, but the fact is that we must compare the arrangements with those existing in other parts of the country at the present time, not with what was common in bygone days, when neither the wants of the population nor the means to satisfy them had attained their present state; and in this respect the North British line between Edinburgh and Dundee is far behind. The Company are thereby even more inconvenienced than the public. The maintenance and working of their ferries at Granton and Tayport cause a very large expenditure. The traffic which can be carried by them is limited, and a great tonnage has to be sent partly over the lines of a competing company, resulting in a serious loss.

[p.41] We may fairly estimate the cost of the ferries and of these adverse circumstances at �70,000 per annum, and it has long been the endeavour of the Company to remedy this state of matters, but they found most serious obstacles in the nature of the two great estuaries which intersect their system.

Mr. Thomas Bouch, their engineer, years ago proposed the bold plan of bridging them both—the Forth at Queensferry, and the Tay about a mile above Dundee. While the desirability of such a scheme was generally recognised, the most sanguine hardly believed that it would ever be realised; but they overlooked the fact that while our wants increased engineering science had not remained stationary, and that by modern improvements in machinery and appliances, facts could now be accomplished which even twenty years ago would have been classed amongst impossibilities. Mr. Bouch’s earnestness and great reputation as an engineer at last gained the victory over the doubt of those who had to support him, and in 1869 the Company applied for and obtained the Act of Parliament which authorised them to build the Tay Bridge, and raise the necessary capital on shares—the North British Railway Company guaranteeing an interest of 5� per cent. from the time the bridge was expected to be finished, viz. three years after it should be commenced. It required no mean amount of confidence and insight on the part of that Company to take this step, and Mr. Stirling and the Board of Directors may well get credit for having shown these qualities; but the chief honour, as the originator of the scheme, will always be due to Mr. Bouch. Others may have anticipated him in expressing a conviction that the Tay Bridge would some day be an accomplished fact, in the same way as one might say that the Channel will be bridged in course of time; but there is a great difference between this and the working out of a plan capable of realisation, and there lies Mr. Bouch’s merit, which cannot be taken from him, whatever may be the result of the discussion as to who was the first to propose that a bridge should be built.

On May 8th, 1871, the next important step was taken, viz. that of entering into an agreement with an experienced contractor for the execution of the work. Mr. Charles de Bergue, from London and Manchester, the accepted contractor, had acquired great fame in the erection of large bridges in nearly all parts of the world, but almost immediately after the signing of the agreement he became seriously ill, so that he [p.42] could not take an active part in the execution. At his death, in 1873, complications arose which had a retarding influence on the progress of the work, and the contract was annulled by mutual consent of the parties, and transferred to Messrs. Hopkins, Gilkes, and Company (Ld.) of Middlesbro’. The writer of these lines acted as their engineer and manager, as he had done for Mr. de Bergue.

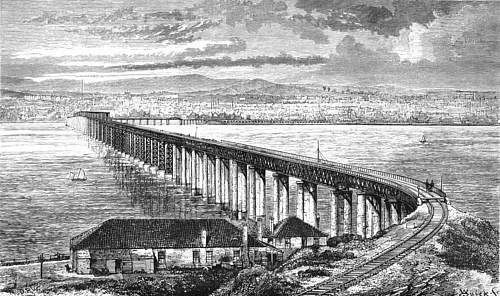

The bridge is now completed. On September 25th the directors and engineers had the satisfaction of crossing it for the first time in a train. Since then heavy ballast-trains have been running over, and as soon as the sidings and stations on both sides are finished it is to be opened for regular traffic, and an opportunity will be given to the public to grumble at something else, viz. that the bridge across the Forth is still wanting to complete the system.

In addition to the local and commercial interest excited by the successful completion of the great work, it must be of great importance in the history of engineering. The thousands of visitors which it attracts from all parts of the country and from abroad afford evidence of the fact that the general public also take a deep interest in the matter, and favour the notion that a description of the bridge, and of the manner in which it was built, without going too deeply into technicalities, will be acceptable to the readers of Good Words.

At the site of the bridge the Firth of Tay is about two miles broad. On the south side trap rocks rise abruptly to a height of about fifty feet out of water; on the Dundee side they have a more gentle slope. In both cases they very soon disappear towards the centre of the river, and are only found at depths which put it out of the question to use them as a foundation for the various piers. Their place on the river bottom is partly taken by clay and boulders, partly by sand; and under the latter, in depths of about eighteen feet, a stratum of gravel is found, which is quite capable of sustaining the weight which is to be put upon it. There are in all eighty-five piers supporting spans of varying lengths, and differing according to the weight of the latter. Those piers which stand on the solid rock are entirely constructed of brickwork set in Portland cement, a substance which in its ordinary state is a fine greenish-grey powder, but when mixed with water it becomes hard in the course of a few minutes, and after two or three days attains a degree of strength which ordinary lime mortar would not have for years. It is therefore of very great importance for all works which have to be carried out under water, as it hardens even better when immersed than when exposed to the air. It plays a most conspicuous part in the construction of the piers, the first fourteen from the south side being entirely built with it up to the very top, and all the others up to five feet above high water, where the ironwork begins. When mixed with sand and gravel, or broken stone, in certain proportions, it forms concrete which takes the shape of any cavity into which it is put, and in a few days becomes as hard as stone. It largely enters into the construction of the lower parts of all the piers, and has the advantage of being easily worked by not particularly skilled workmen. Without this, or some substance of similar properties, the building of the Tay Bridge would in all probability have been impossible.

Scaffolding

The piers which are not founded upon rock require, of course, an extended base to carry the great weight with safety. The former consist of two cylinders of nine feet six inches diameter, while those standing on gravel, and supporting spans of the same length, have the diameter of these two cylinders enlarged to fifteen feet, and their top weight is greatly reduced by substituting for the heavy brickwork above high water, cast-iron columns, fixed together by horizontal and diagonal transverse bracing.

Thirteen of the spans over that part of the river which is generally used for navigation are two hundred and forty-five feet long, and the piers are so high that at the highest water there are eighty-eight feet of clear waterway left—more than sufficient for the class of vessels plying from Dundee to places above bridge. The girders composing these spans are placed so wide apart that the trains can pass between them, the roadway being fixed at the bottom of the girders. In the other parts of the river this great height is not required, and the piers have therefore been kept much lower, the top of the spans in this part being level with the bottom of the large ones, and the rails being laid on cross sleepers resting on top of the girders. In this manner the roadway forms an unbroken line, while there seems to be a step in the girders—a circumstance which puzzles many, till a walk on the structure has shown them that the engines will not by any means have to perform the wonderful acrobatic feats which a view from a distance would lead one to expect.

[p.43] On the Dundee side the line has to pass the town underground, and the station is another “laigh shop.” To reach it the line must come down in time from its lofty position, and an incline of one foot in every seventy-three of length is therefore introduced in the part north of the large spans. The length of the spans on this part varies from one hundred and sixty-two feet to sixty-nine feet, and quite near the shore a large span of one hundred and seventy feet is constructed, with a view of offering facilities for a future extension of the esplanade, which would necessitate the construction of a roadway under this span. For the same purpose it is built on the “bow-and-string” principle, and the rails kept at the bottom. Parallel girders, like those of the large spans, might of course have been used; but what is no disfigurement when carried out over a great length would look very bad indeed if applied to a single span. Now the curved top-boom makes the transition an easy one. The last six spans on the Dundee side, so far as they belong to the Tay Bridge contract, are short ones, being only twenty-seven feet long. Three more of these, and a “bowstring” of one hundred feet, complete the iron part of the bridge, bringing the total length to ten thousand six hundred and twelve feet, or two miles and fifty feet.

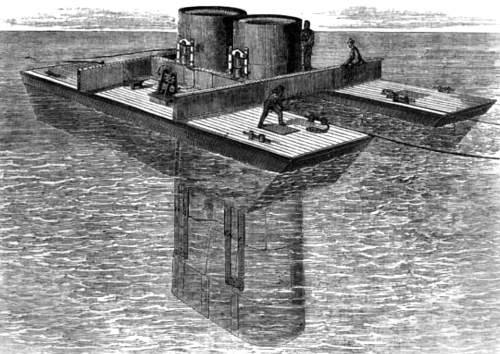

Floating Out

On the south side the same reasons for constructing a strong incline did not exist. As the land at the south shore is about seventy feet above high water, an easy slope of one foot in three hundred and sixty-five was sufficient to bring the line to the required level. The spans on that side are mostly of one hundred and forty-five feet and one hundred and thirty feet in length. There are only two of eighty-eight feet and three of sixty-seven feet near the shore.

To complete the general description of the bridge, it will only be necessary to mention that, in order to join the land portions of the line, a long curve had to be introduced on the north side extending over nearly a quarter of a circle, and one of less length on the south side, giving the bridge in plan the appearance of a gigantic S. From the shore the curves, especially the one on the Dundee side, appear to be very sharp, but in reality they are not, both having a radius of twenty chains, while on other lines curves of eight chains are frequently met with.

Let us now look at the means which were employed to construct this, the longest bridge in the world. Quite in the beginning Mr. Austin, another of Mr. de Bergue’s managers, laid down a principle which was of the greatest bearing on the success of the work. It was to dispense with the staging and scaffolding which are generally used in bridge building. The piers and girders were to be erected on shore, and floated out to their destination. The consistency with which this principle was carried out would distinguish this bridge from all other structures of the same kind, even if its size and importance were less remarkable. No matter of what material the parts were constructed, whether they were iron receptacles for concrete, huge lumps of brickwork weighing above two hundred tons, or iron girders of one hundred and ninety tons, they were all finished on shore and floated to their destination. During the execution the details had frequently to be modified to suit the altered circumstances, but the principle was adhered to as the only one which could produce good results in a tidal river subject to such vicissitudes, and with a continually shifting sandy bottom.

Previous to the execution of any permanent work a great amount of preparation had, of course, to be made. In addition to the erection of the usual offices, workshops, and stores (to which in this case a kitchen, dining-room, and dormitory for the men were added), a large part of the foreshore on the Fife side had been levelled and provided with a concrete floor on which the piers could be built. For the smaller piers the whole lower part up to low water was built up there: an iron shell with brickwork in it, leaving a hollow in the centre.

As every six hours the tide left the level floor there was no difficulty in this. At a rising tide two barges were then brought alongside the pier and fastened to it, so that a further rise of the water must necessarily lift it off its resting-place, and keep it suspended between the barges, in which state it was towed out to its destination and lowered by means of specially constructed hydraulic apparatus, till it stood on the river bed, after which the connection between it and the barges was severed, so that a rising tide would clear the latter and leave the pier standing on the rivet bottom. It had now to be sunk to the rock, and for this purpose the top was closed and air pumped in, which, by exerting a pressure on the water inside, would force it out below till the pier was quite dry, so that workmen could descend in it and excavate the material at the bottom. This was sent up in buckets and discharged into the river, special measures being taken [p.44] to prevent the compressed air from leaving the cylinder during the passage of materials or men, as otherwise the water would have entered from below. The pier would of course sink by its own weight as the excavation proceeded, and when the rock was reached the working chamber at the bottom and the central shaft were filled with concrete, making the mass a solid piece of brickwork and concrete encased in iron and resting on the rock.

For the large piers founded on gravel a somewhat different process was adopted. For these it became expedient, first, to construct an artificial rock capable of carrying the enormous weight of pier, superstructure, and train. A cylinder of thirty-one feet diameter of malleable iron plates was first built on the level floor on the foreshore. As far as it had to penetrate into the ground, it was provided with a lining of brickwork. This height was generally about twenty feet. Above that point the cylinder consisted of iron only. Its purpose was simply to extend the pier to above the water-line, and thereby to afford means to handle the mass, to protect the divers working in it during the sinking against the strong current, and to give those in charge of the work an opportunity of judging of its position. This part was only temporarily fixed to the lower or permanent part, and could be taken off and used again after having answered its purpose.

When completely erected on shore, the structure had a height of forty to forty-four feet and a diameter of thirty-one feet, and resembled in appearance a huge gasholder. Its weight was about two hundred tons. Two large barges, one on each side, were fastened to it, and as described for the smaller piers, the rising tide would lift it off its resting-place, and it could then be towed out to its destination and lowered down on the river bed. Our illustration shows one of these foundations floating between the barges and ready to be towed out.

It was a curious and interesting sight—this ponderous mass handled with as much ease and precision as if it were a small model instead of a gigantic cylinder of seven hundred square feet area, and more than twenty-eight thousand cubic feet contents. Securely fastened to the barges, it could weather the strongest gales.

II.

[p.103] THE very first foundation, floated out on August 27 th, 1875, was severely tested by the weather. When it left the shore in tow of two steamers a gentle breeze was blowing, but by the time it reached the place where it had to form part of the bridge the breeze had increased to a strong gale, and the waves washed over the barges so that the hatchways had to be caulked to prevent filling and sinking. It was left in that position nearly three days till the gale moderated sufficiently to allow the operation to proceed. With the smaller piers this could not have been done. They weighed only from forty to eighty tons, and were entirely at the mercy of waves which on the larger ones produced little or no effect. In another important point did these large piers show their superiority over the others. Their base was so much larger that there was no fear of falling over—as three of the small ones had done—even if they should go a few feet out of level during the sinking.

Now one must remember that these cylinders had only to penetrate the sand, and that no clay, boulders, or such material had to be excavated. In order to sink the cylinder it was only required to make a large hole in the centre into which it would sink till it reached the firm bottom. It was, therefore, not attempted to get it dry by forcing air into it, but pumps placed on barges were applied, and the end of the suction pipes guided by divers at the bottom of the pier. This apparatus, invented by Mr. Reeves, one of the assistant engineers, differed from an ordinary pump in this respect, that the sand and water could not come into contact with the valves and other working parts, which they would soon have rendered unfit for use by their grinding action.

The Tay Bridge - from the South Side

The apparatus was placed on a barge so that it would be readily removed in case of a gale. In ordinary weather the sinking of these cylinders took about fourteen days; but often they could not be approached for weeks in succession, and the average time of sinking was thereby increased to one month. After it was accomplished concrete material was lowered down in buckets which opened when they reached the bottom, and this was continued until the whole lower part of the cylinder, extending from the gravel to a few feet above the river bed, was filled. During the latter part of this operation divers spread the concrete to obtain a level surface. It was now only necessary to remove the top iron part, leaving the lower part to form an artificial level rock of great surface. In the meantime, the brick part of the piers had been built on shore. On the level floor two iron girders were placed to be built in and become part of the brickwork, so that it could be lifted by their projecting ends after the cement had become so hard as to make the whole mass as strong as if it had been hewn out of one stone. It might easily have got cemented to the level floor also if a layer of brown paper had not been spread on this before building the brickwork. This part of the pier was hexagonal in shape, and when placed in position would have two points up and down stream forming cutwaters, while two of the sides ran parallel with the direction of the current. An opening was left in the centre to lighten the mass while it was floated, and this was filled up with concrete after the pier had been placed on the foundation, so that it became one with the concrete in the lower part. When finished the pier would be sixteen feet wide and measure twenty-seven feet in the direction of the current. Three or four of these brick blocks, twenty-two feet high and weighing two hundred tons, were always kept ready on the foreshore and floated out in turn, so that they might have as long a time as possible to get thoroughly hard or “set.” After floating out they would only reach a few feet above low water, but as the tide left the top for a shorter or longer time, it was easy to add to their height and build them up to high water by bringing barges containing materials and men along side of them. Four [p.104] courses of stone of an aggregate thickness of five feet were afterwards put on and completed the pier to five feet above high water. In the meantime, the pieces of iron forming the girders or spans had been erected and riveted together on a staging near the shore and connected with it by a gangway. Some of these pieces as they arrived from the contractor’s works at Middlebro’ were thirty-five feet long and weighed three tons. Each span had four horizontal pieces or booms, two at the top and two at the bottom, and four vertical posts at the ends. Nine crosses consisting of struts and tie-bars keep the booms at the proper distance and transmit the strains to the ends where the span is supported by the piers. The two girders of each of the two hundred and forty-five feet spans are fifteen feet apart, their depth is twenty-seven feet, and their weight one hundred and ninety tons. To erect and rivet them on the staging required four weeks, not fewer than eighteen thousand rivets having to be put in each. After completing that work the staging on which it had been done was partly demolished at each end and barges introduced in the gaps. These would lift the span off its temporary resting place and float it out to the piers, which were ready to five feet above high water. Here they were moored and left to wait the falling tide, which deposited the ends on the piers and cleared the barges. It generally took less than half an hour to take the heavy mass from the staging to its place, and all went smoothly and without any trouble. Occasionally, however, the success of the operation would be endangered by a sudden gale. This was especially the case on August 23rd, 1876. A steady breeze was blowing at the time, but as the floating out of the girder had already been delayed a couple of days, it was resolved to take it out notwithstanding. As high water would occur at seven o’clock in the evening the barges were put in the gaps of the staging under the girder at four o’clock and shortly after touched it and began to take the load. At six o’clock it was high enough to be floated away, but as the current was yet too strong it had to wait In order to counteract the westerly breeze to some extent by the last of the flood-tide, it was towed away at half-past six. The wind had in the meantime risen to half a gale, but the barges with their strange load proved to be quite seaworthy, and the operation would not have been marked by any extraordinary circumstances had both the tug steamers been equally well prepared for the work. But one of them had been hired for the occasion and was not well arranged for towing. She soon turned out to be quite useless, and the other was not able to keep the girder broadside on against the wind, even with the tide in its favour. The structure was blown down the river, to the dismay of a number of interested spectators on board the steamer and of the on-lookers on shore. In order to offer as little surface to the wind as possible, the girder was put end on, but as the ebb-tide had now set in all it could do was to retard the downward course.

Another trial was made to get help from the second steamer, but the crew had evidently got demoralised and the high wind made it impossible to make the orders given from the girder understood by those on board. One rope after another snapped, and every time the chance of reaching the piers, or even a sheltered place for the night, was lessened. The girder had already drifted more than a mile and would soon come to the mouth of the river. Darkness was fast setting in, the tide was flowing away and would soon be too low to float the girder over the top of the piers on which by this time it should have rested. It was a very anxious time for those “on board.” It was difficult to tell what would happen, but all the contingencies were bad ones, the probability of mooring the barges with their freight in the river and riding out the gale being one of the most favourable suppositions. If the weather did not get worse and heavy anchors could be procured soon enough, this might be done; and one of the launches had been dispatched for the purpose of getting them, while the other was away to Dundee to get another tug if possible. In the meantime the spectators had left in the second steamer, as it had become quite dark. Not one of them was prepared to see the girder next morning in its proper place, but as soon as the harbour steamer arrived in response to the summons for assistance, a temporary lull set in, and the two tugs managed to get the girder up to the place just in time. Five minutes later and the piers would have been too high out of the water. As it was, it was safely resting on them by eleven o’clock, and the barges were withdrawn soon after and taken into the harbour. When by midnight the gale came on again with full strength the writer derived no small amount of satisfaction from the thought that the structure was in safety. No moorings would have stood such a wind and the girder would surely have been wrecked.

[p.105] As we shall see, it could not escape its fate for all that. Six months later it came to grief by even a fiercer gale, after having been raised to its full height of eighty-eight .feet. The lifting of the girders to their exalted position was not a very difficult matter, the apparatus having been specially designed for it, though it required great care and attention. From a distance it seemed wonderful to see them creep slowly up at the rate of twenty feet per day. The distance from both shores being so great it was impossible to discern any of the men and appliances, although about eighty of the former were employed in this work. Some had to work the pumps which supplied the pressure for the hydraulic apparatus. Others had to manipulate the cocks and pins by which the weight was alternately released and taken by the rams. Then again a set of machinery had to be got ready on a higher stage by the time the girder should reach it; and, lastly, the ends of the structure had to be closely watched in their upward course so as not to come in contact with projecting parts of the columns, and the bracings connecting these with each other had to be put in as the girders rose. When the spans reached the top the heads of the columns were firmly connected with a set of girders carrying the bedplates, but before the weight could be put on these the span had first to be connected with the adjoining one. While that connection was being made the other end of the spin was lifted up about six inches, so as to produce a strain in the connectives when lowered down to its permanent position. This took several days to accomplish; and during all that time the girders had to be left hanging in the lifting apparatus, and were of course at a disadvantage against the influence of the winds compared to what they would be when permanently fixed.

When the girder which had given so much trouble at the floating was in this position, a violent gale sprung up. Since 1871 the storm had not raged with such fierceness as on the night of February 3rd, 1877. Without any barometrical warning, it came down at four o’clock in the afternoon with an unparalleled suddenness. No gradual growth, no preliminary showers heralded its approach. It was just high water, and a very high springtide it was. A steamer was sent to take the men off the piers but could not even get near them. The large pontoons in the harbour on the south side and several barges were torn from their moorings and only secured with the greatest difficulty, the sea washing right over the landing jetty and stagings.

It was now quite dark and nothing could be done to release the forty men yet out on the high girders. They could come down from that position to one of the adjacent girders which had not yet been lifted, but as a small “bothy” had been erected on the high one it was probable that they would seek shelter there. The Sunday before the girders had weathered a very heavy gale without being at all affected by it; but if ever anything could happen it was in the position in which they were now. By eight o’clock the steamer Excelsior made another attempt to reach the men, or at any rate to get near enough to speak to them and show them that they had not been forgotten. When within two hundred yards of the spot the crew heard a frightful crash and then a splash in the water which sent the spray over the deck. They knew that at least one girder had come down, but a fire on the lower one reassured them about the fate of at least some of the men. Loose planks and wreckage now came down upon the steamer and she had to hold off again, and it was not till four o’clock in the morning that the sufferers were at last taken on board and brought to Dundee, where anxious wives and mothers were waiting for them on the quay. With the exception of one all were saved. Not one had been on the fallen girders, though a few went up but a short time before the catastrophe to get their coats. The missing man had been seen shortly before the steamer arrived, and must have fallen off the pier or missed his footing at the embarkation. In the prevailing darkness and confusion this might easily have happened without being noticed. The foreman had one of his legs broken but none of the others were hurt, and the chief anxiety, that many or all of them might have lost their lives, was fortunately allayed.

At daybreak the full extent of the disaster could be realised. Two of the large spans and one girder of the one hundred and forty-five feet span adjoining them, together more than four hundred tons weight, had come down. The iron part of the piers on which they were supported was completely wrecked, but fortunately the brick and stone part of the piers was uninjured. The accident was, doubtless, a very serious one, and would occasion great expense and delay; but the thought that it might have been ever so much worse, and that after all the loss of property was nothing compared to all the [p.106] human lives which had so mercifully been saved, was a great consolation.

The fallen girders had to be removed, and new ones built, and the piers to be erected again; and this threatened seriously to interfere with the expectation of having the bridge finished for the passage of a train by September. Only eight months were now available for the erection and floating out of six, and the lifting of ten, two hundred and forty-five feet spans. Five and seven respectively of the one hundred and forty-five feet spans had yet to go through the same processes. Seven large and three small piers had yet to be built. The weight of iron which had to be put in its place was 2,700 tons, and it seemed incredible that all this could be done in eight months. A good deal would depend on the weather, but this was far from favourable. During February there were only five days on which work was possible out in the river, and the spring and summer of 1877 will certainly be remembered by bridgebuilders, sailors, and farmers as the most unfavourable they have known for a good many years.

The contractors did their best to counteract these evil influences, and

by putting extra pressure on their workshops, by working day and night

at the bridge works, by the aid of powerful electric lights, and by

engaging a greater number of men, they succeeded, almost against their

own expectation, in having the last rail laid on September 22nd, and

crossing with an engine the same day. Probably there has never been so

much work done in so little time, and under such adverse circumstances,

as was performed at the Tay Bridge during the last eight months of its

construction.

1 June - short

biography, births, deaths

and events on date of opening of the original Tay Bridge.

1 June - short

biography, births, deaths

and events on date of opening of the original Tay Bridge. 25 February

- short

biography, births, deaths

and events on date of Bouch's birth.

25 February

- short

biography, births, deaths

and events on date of Bouch's birth. Beautiful

Railway Bridge of the Silvery Tay: Reinvestigating the Tay Bridge

Disaster, by Peter R. Lewis. - book

recommendation.

Beautiful

Railway Bridge of the Silvery Tay: Reinvestigating the Tay Bridge

Disaster, by Peter R. Lewis. - book

recommendation.

Thomas

Bouch: The Builder of the Tay Bridge, by John Rapley - book

recommendation.

Thomas

Bouch: The Builder of the Tay Bridge, by John Rapley - book

recommendation.